Emergency situations do not necessarily arise only from natural disasters or fire emergencies. Sometimes, all it takes is a little miscommunication on the floor workspace or a clumsy spill of a hazardous material for an injury or an accident to happen. As such, it is not only emergencies of destructive nature that general occupants must prepare for, but also those that could occur in the workplace, from the work materials.

In determining safety in the workplace, it is important to note that while some items are not guaranteed to jumpstart an emergency, they do have the potential for it. As such, the occupants or employees must at least be given proper warning as to the dangers associated with whatever is identified to be a risk or a hazard.

When engaging in risk assessment practices, there are four important things that must be accounted for, these are best remembered through the acronym S.A.F.E.

S – Spot the hazard

A – Assess the risk

F – Fix the problem

E – Evaluate the results

Defining Hazards

Strictly speaking, hazards are sources or situations that carry the potential of harm or loss, according to the Australian Standard 4360 Risk Assessment and Australian Standard 3931. It can be embodied in a host of forms, such as:

- Equipment hazards

- Physical hazards (extreme temperatures, noise, vibration hazards)

- Chemical and biological hazards (hazardous substances/ lack of cleaning)

- Traffic movements (unsafe vehicle use/ inadequate lighting)

- Handling and storage of materials (lack of appropriate processing devices or improper storage techniques)

- Contractors and visitors (lack of supervision and training on safety systems)

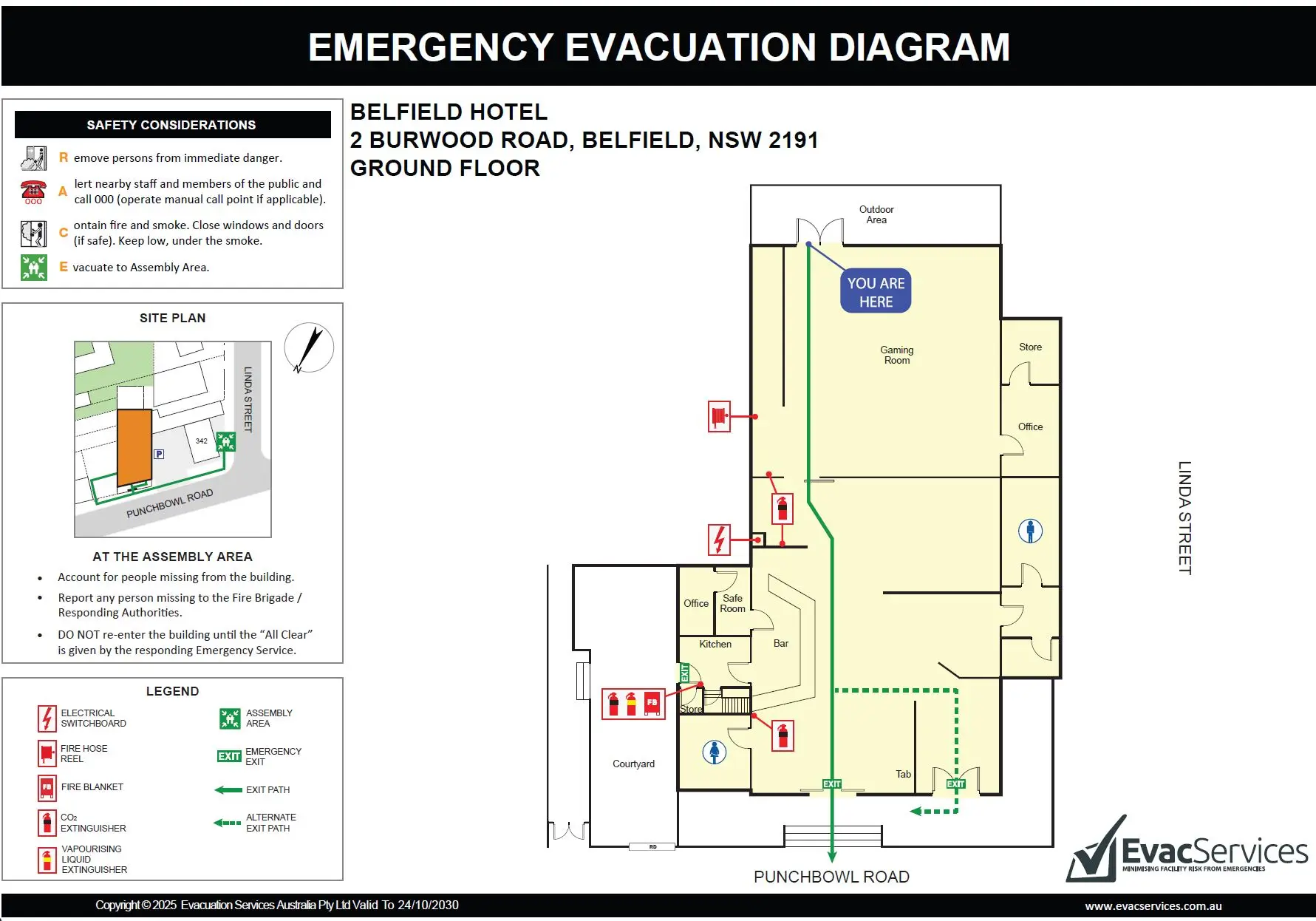

Ideally, the building or the office would have in place proper emergency procedures to ensure that each and every person would have a chance at being able to stay safe, whether through first aid methods or evacuation procedures. These will ultimately depend on the building structure, as well as the specifications of the workplace, and must be clearly identified in the emergency procedure manual, the OH&S manual, or any other standard operating procedure.

Spotting the Hazard

A problem cannot be fixed unless it is clearly identified. For this particular task, the Chief Warden is primarily responsible for carrying out the assessment process, which includes the identification, reporting, and controlling of hazards.

There are several ways to do this to keep the workplace safe, and one of the most reliable methods is to ask the people themselves. This is particularly important for those making the evaluation because while they may not necessarily be up to speed as to the real situation on the floor, the workers most definitely are. From their position, they can have a more definitive picture of what kind of problems they usually encounter while doing their day-to-day tasks, and if any of these pose a danger to their safety.

Aside from questioning the workers on the floor, however, it is still best to set out on a thorough inspection by the assessment team. The layout of the workspace must also be considered, including the equipment and machinery, appliances and furniture, and even vehicles. Exit points, driveways, and housekeeping guidelines must also be up to par with the safety standards. Storage, usage and movement of substances, if there are any present in the workplace, must also be accounted for.

All these items and more are included in the checklist provided in Australian Standard 1851. Consultation with the OH&S Committee members and other specialist providers are also recommended.

Because of the varying expense of workplaces, the procedures for identifying hazards and what classification or type they fall under will most certainly cover quite an expansive range. The important thing here is that whatever observations are made, they should be systematically logged so that a proper analysis and evaluation may be duly determined based on the gathered information.

There are those hazards that are more obvious, more visible, and easier to deal with than others. Opposite of that, though, are those hazards that are a bit more innocuous, and therefore trickier to spot, and more difficult to address.

Risk Assessment

The point of assessing risks is not only to identify them but more importantly, to effectively mitigate or eliminate the dangers that may arise from it. Risk assessment should also come in handy to rank and prioritise the risk, from the most dangerous to the least. This way, commensurate actions may be had in response to the gravity of the situation. Obviously, the bigger the risk is, the more immediate the response must be. The less danger there is, the more that it can be addressed later on.

To properly identify what are potentially dangerous in the workspace or building, a thorough examination of every nook and cranny, every equipment and substance, must be made. Housekeeping policies, standards, and practices must also be reviewed to determine if there is anything that could lead the occupants to danger, or if it could present an emergency situation.

As soon as a conclusive identification is made, the level of potential damage and its likelihood of occurrence must also be evaluated. Through workplace risk assessment, workplace hazards management becomes more feasible and gives the opportunity for proper emergency procedures to be carried out.

With the risk and hazard properly identified and assessed, a clearer perspective may, therefore, be had, exhibiting the Likelihood of an emergency occurring (frequency of it happening), as well as the Consequences that may arise from it (expected effects/ repercussions). These two factors are also what will be used as matrices to lay out more effective standard or procedure.

Fixing the Problem & Evaluating the Changes

Of course, the entire point of risk assessment is not only to tag away at the potential sources of danger. The very objective of this exercise is to remedy these hazards and risks by implementing necessary changes in procedures or providing improvements to the equipment or infrastructure.

After the fixes have been put in place, it is then imperative that an evaluation of the same is carried out. This is to guarantee that the implemented solution is indeed commensurate, or does address the problems identified. If not, then adjustments or improvements could be made, until such time that the problem is certainly fixed.

Workplace risk assessment and hazards control is a tedious process, but as it is one of the more important things that can guarantee safer and better workplace conditions, then it must be non-negotiable. Consider this as one of the foundations of a sound workplace safety standard for the benefit not only of the workers but also for the general occupants of the building.

For more information visit EvacServices or take the 100% Compliance Survey to check the compliance status of your building.